Asset owners and asset managers all understand that meeting regulatory standards and the ability to demonstrate compliance are essential. Not only because of the significant losses which will be incurred if a License to Operate is withdrawn. It stands for meeting HSEQ requirements; to operate safely and avoid incidents and accidents from happening. To protect your employees, the environment, your customers and your organization. To build and maintain trust. Managing compliance is an integral part of managing asset performance and does not have to be a burden but can be of valuable help.

How We Help

Proving Compliance

Managing Asset Integrity is an essential part of demonstrating compliance. We help, within the boundaries as set by regulations and your own internal policies, to introduce and apply a Risk Based Inspection (Integrity) method (RBI). We assist with prioritizing your efforts; to apply the right inspection methods and introduce other risk mitigating measures. We do this in a transparent, well-documented process.

This includes professionally and properly defined remaining lifetimes and it also opens the door to Asset Lifetime Extension studies, postponing and optimizing shutdowns and turnarounds. All based on demonstrated risk management.

Meet the Organizations Already Boosting Their Performance with MaxGrip

25%

Decrease of the backlog

Permit to Work

Permit to Work, also called Plant Clearance, is critical to demonstrate compliance and manage risk in Oil & Gas, Chemicals and Power industries. Operators and field technicians should manage specific hazardous work with, for example, high-voltage equipment or chemical substances with care to reduce the risk of incidents and accidents to occur.

These activities are often not routine but dangerous which heightens the need for a competent workforce that can perform the activities, take necessary precautions, follow a stringent process and log data and information as required. Furthermore, communication between maintenance and operations needs to run smoothly to align on preparation, execution, reporting and handover. MaxGrip can help out to account for all of these factors.

Get inspired

We share our view on 25 years of maintenance and asset performance management.

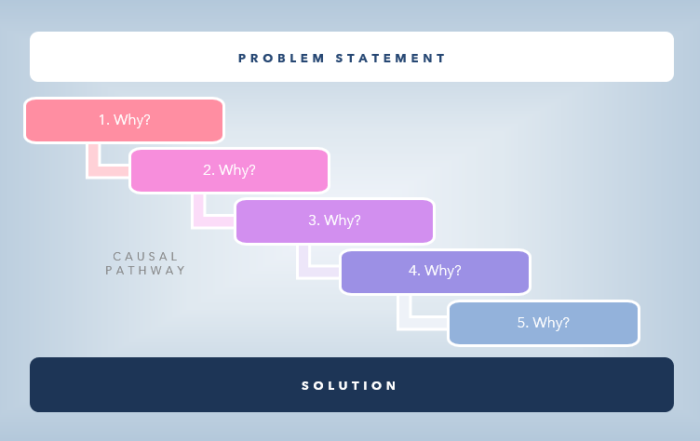

In this toolkit, gain access to spreadsheet and infographic templates to get started with a Five Why technique root cause analysis

MaxGrip is honored as the 2024 innovator in asset management by Verdantix, leading with cutting-edge technologies and practices. Join our webinar on May 22nd to discover more.