Adequate Asset Integrity Management is crucial for companies in asset-intensive industries. Not only as their performance relies heavily on the proper function, but also because failure of these assets can have a major impact on safety and the environment. Asset Integrity Management is an integral part of a risk management program, essential for minimizing various risks and enabling informed equipment strategies. This is why many companies operate in a regulated environment and have to demonstrate compliance to the authorities to obtain and maintain their License to Operate. Even if not regulated, it is just as important for other companies. Additionally, companies have to demonstrate how they will maintain asset Integrity if they want to extend the lifetime of their assets. MaxGrip has a wealth of experience and expertise in the domain of asset integrity; from greenfield to brownfield to Asset Lifetime Extension (ALE) across sectors. We are expert in working with the Inspection departments as well as to relate this to the scope of the Maintenance and Operations departments.

Why is Asset Integrity Management Important?

Asset Integrity Management is essential for maintaining the performance, safety, and reliability of physical assets, leading to enhanced operational efficiency, resource optimization, compliance with regulations, and cost savings.

- Safety and Compliance: Ensuring the structural integrity and safe operation of assets is paramount to protect human lives, the environment, and if applicable to comply with regulatory standards. Failure to do so can result in accidents, legal consequences, loss of reputation and also loss of production.

- Operational Reliability: Proper AIM ensures that assets perform their required functions while safeguarding health, safety, and environmental aspects. This leads to fewer unplanned downtimes and interruptions, enhancing productivity and operational reliability as well as a safe place to work for the staff, for contractors and the safety of the outside world.

- Cost Savings and Economic Benefits: Implementing effective AIM strategies, such as Risk-Based Inspection (RBI) and Asset Life Extension (ALE) studies, can lead to significant cost savings. For instance, the RBI revalidation in a GTL plant resulted in savings of over $1.7 million per leak, and RBI assessments have saved oil and gas producers significant amounts annually by optimizing inspection and maintenance efforts.

- Asset Life Extension: AIM plays a crucial role in extending the operational life of assets beyond their original design life, ensuring they can continue to operate safely and efficiently. This shows senior management the business case and, if relevant, provides evidence to the regulator. Such scenarios also include the best way to manage Asset Integrity during the extended period. This not only defers the substantial costs associated with replacing assets but also maximizes the return on investment from existing assets. Additionally, AIM integrates end-of-life strategies such as phased decommissioning, repurposing for less critical functions, or upgrading to meet new operational demands. These strategies ensure that assets continue to contribute value, align with safety standards, and adhere to environmental regulations, ultimately supporting sustainable and cost-effective operations.

- Data and Technology Integration: Modern AIM approaches integrate data analytics, predictive maintenance, and other Industry 4.0 technologies to enhance decision-making and operational efficiency. This enables organizations to move from reactive to proactive and predictive management of asset integrity.

- Sustainability and Environmental Stewardship: By ensuring the integrity and optimal performance of assets, companies can minimize the risk of environmental incidents and contribute to sustainable operational practices.

Watch Now

Our Asset Integrity Approach in 95 Seconds

Why Partner with MaxGrip for Asset Integrity Management?

MaxGrip consultants provide full asset lifecycle management services for all disciplines

Our comprehensive approach to Asset Integrity Management (AIM) encompasses the entire life cycle of assets, ensuring their reliability, integrity, and availability from initial deployment through to potential life extension. By leveraging our extensive expertise in Risk-Based Inspection (RBI) and utilizing RBI software, we provide clients with thorough assessments and strategic maintenance planning. This proactive management not only supports assets operating within their original design life but also facilitates the safe and efficient extension of asset life where applicable.

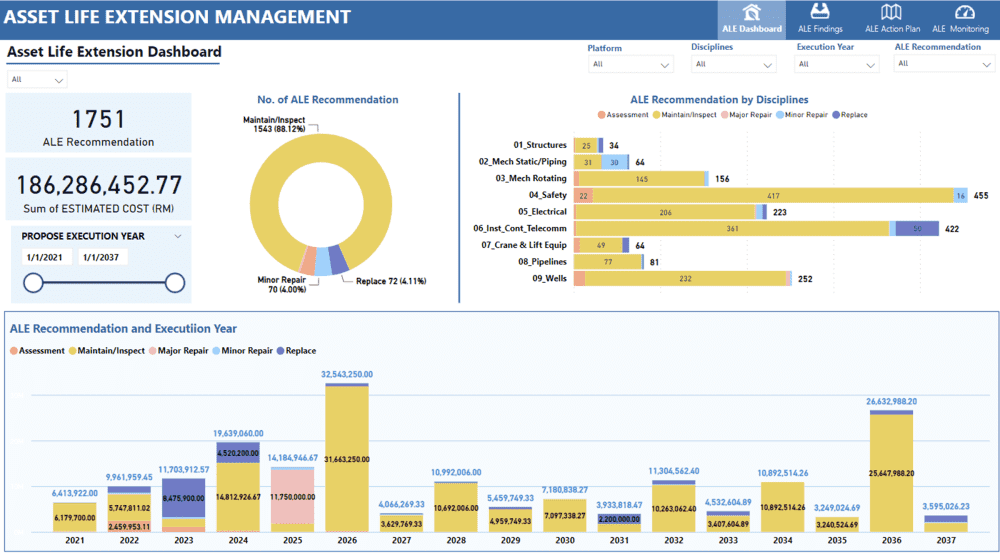

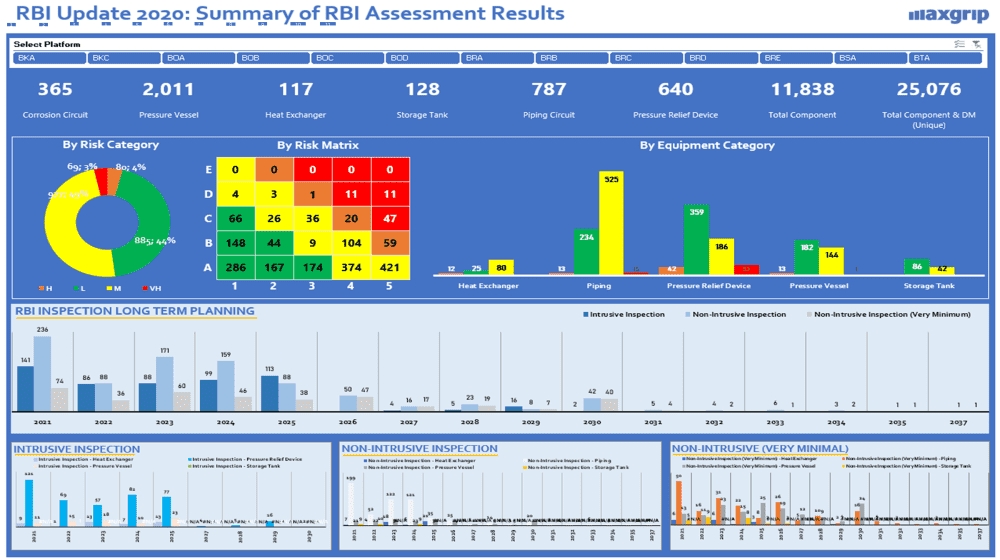

MaxGrip’s Asset Lifetime Extension (ALE) approach results in a realistic ALE deployment program and cost reduction through an extension of assets beyond their original design lifetime. In addition, MaxGrip consultants offer access to bespoke asset integrity data dashboards, which are instrumental in enhancing decision-making processes. These dashboards have proven to be beneficial for planning optimization, ALE management and continuous improvement for asset performance.

How We Help with Asset Integrity & Assurance

We are 100% compliant to industry practice and local regulatory requirements. Our MaxGrip integrity management experts have knowledge of and experience in all disciplines, including static, piping, cranes, vessels, pipelines and structures. What MaxGrip offers in the area of asset integrity and assurance can be roughly divided into three groups: support (staffing), consulting services and the MaxGrip Asset Improvement Program.

Asset Integrity – Support

MaxGrip experts have the competencies and the expertise to get the job done. They can support effectively and efficiently fulfil roles in your integrity or inspection team and are quickly up and running to add value to produce output. You can think of corrosion engineers, RBI analysts, data integration consultants, material experts, strategy consultants, (session and workshop) facilitators, planners and schedulers and project managers.

Risk Based Inspection – Consulting

Risk-Based Inspection (RBI) is well-known in energy industry and widely used in various industries to improve the operating expenditure cost (OPEX) and at the same time provide flexibilities for asset owners in optimizing long-term inspection planning and corrective maintenance programs.

MaxGrip helps clients to achieve these objectives by providing cradle to grave RBI consultancy services in terms of asset register data review and screening, Probability of Failure (PoF) & Consequence of Failure (CoF) assessments, risk analysis assessments & ranking, updating inspection service plans with findings.

Our expertise in RBI or Asset Integrity spans a comprehensive range of equipment, ensuring optimal safety, reliability, and performance across various industrial sectors. We specialize in static equipment such as pressure vessels, storage tanks, heat exchangers, pipelines, and boilers, conducting thorough assessments to prevent issues like corrosion, fatigue, and operational stress. Our capabilities extend to rotating equipment, including pumps, compressors, and turbines. Additionally, we focus on electrical and instrumentation systems as well. We are also able to include structural integrity by inspecting support structures and foundations for signs of corrosion, fatigue, and mechanical damage. In essence, our robust and expansive asset coverage ensures that we deliver value-driven, risk-based inspection services tailored to a diverse portfolio of assets.

Asset Lifetime Extension – Consulting

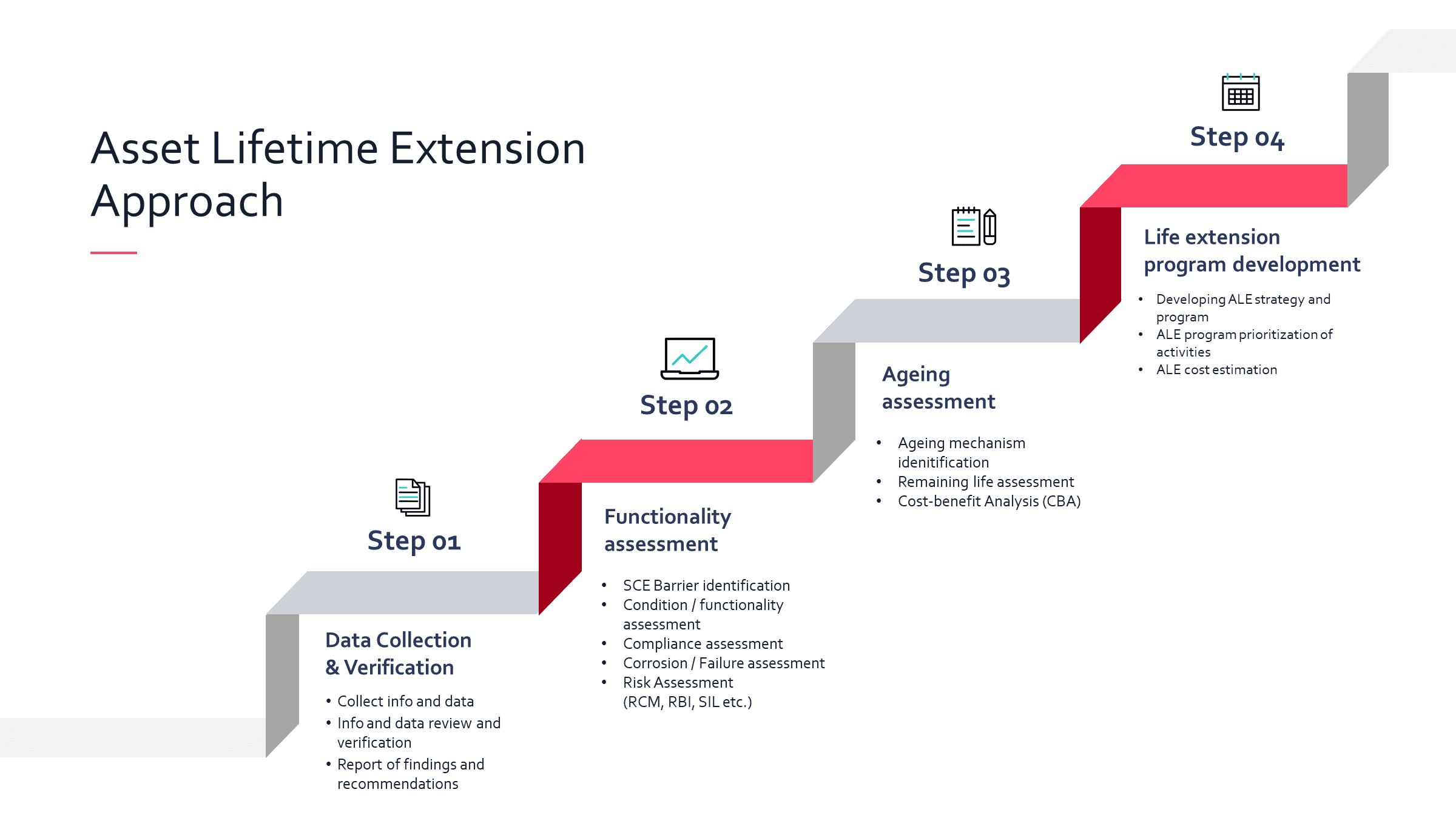

Our Asset Lifetime Extension (ALE) approach delivers a realistic deployment program, which is justified by an underlying business case and will extend operations beyond the assets’ original design. We can provide asset life extension assessments based on different scenarios that consider cost, identify risks associated with the remaining life of the asset, consider different asset extension times, formulate the recommendations to safeguard the reliability & integrity for the intended extended life and also create a monitoring program which includes the clarification of associated cost.

Asset Data Management and Dashboards

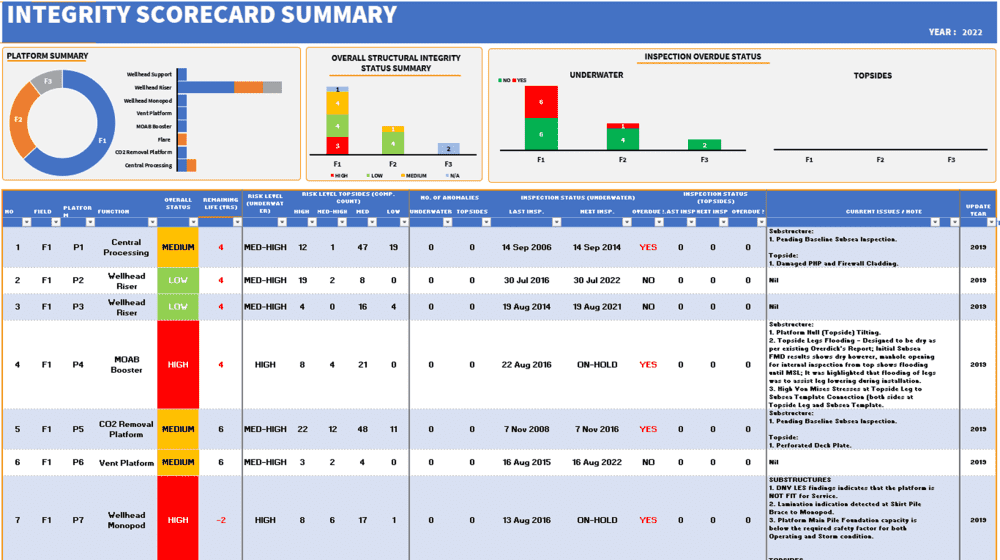

MaxGrip consultants can provide reliable and transparent risk & condition monitoring through bespoke KPIs and dashboards. These customized asset integrity dashboards give an overview of the current status and will give recommendations and cost estimations for different scenarios.

Frequently Asked Questions About Asset Integrity Management

How do you ensure asset integrity?

Ensuring asset integrity involves a multifaceted approach that includes comprehensive planning, implementation of various strategies, and continuous improvement based on assessment outcomes. Here’s a breakdown of key strategies and practices drawn from the documents:

- Risk-Based Inspection (RBI) and Revalidation: Implementing and revalidating RBI methodologies is crucial for maintaining asset integrity. For instance, in one case, RBI revalidation for a GTL plant led to significant cost savings per leak prevented, a 10% reduction in man-hours needed for preparing work packages and turnarounds, and enhanced integrity safeguarding the license to operate.

- Maintenance and Inspection Optimization: Optimizing maintenance and inspection strategies, such as through RBI assessments, can lead to substantial cost savings, reduced man-hours for inspection and maintenance, and extended inspection intervals for a significant portion of the equipment.

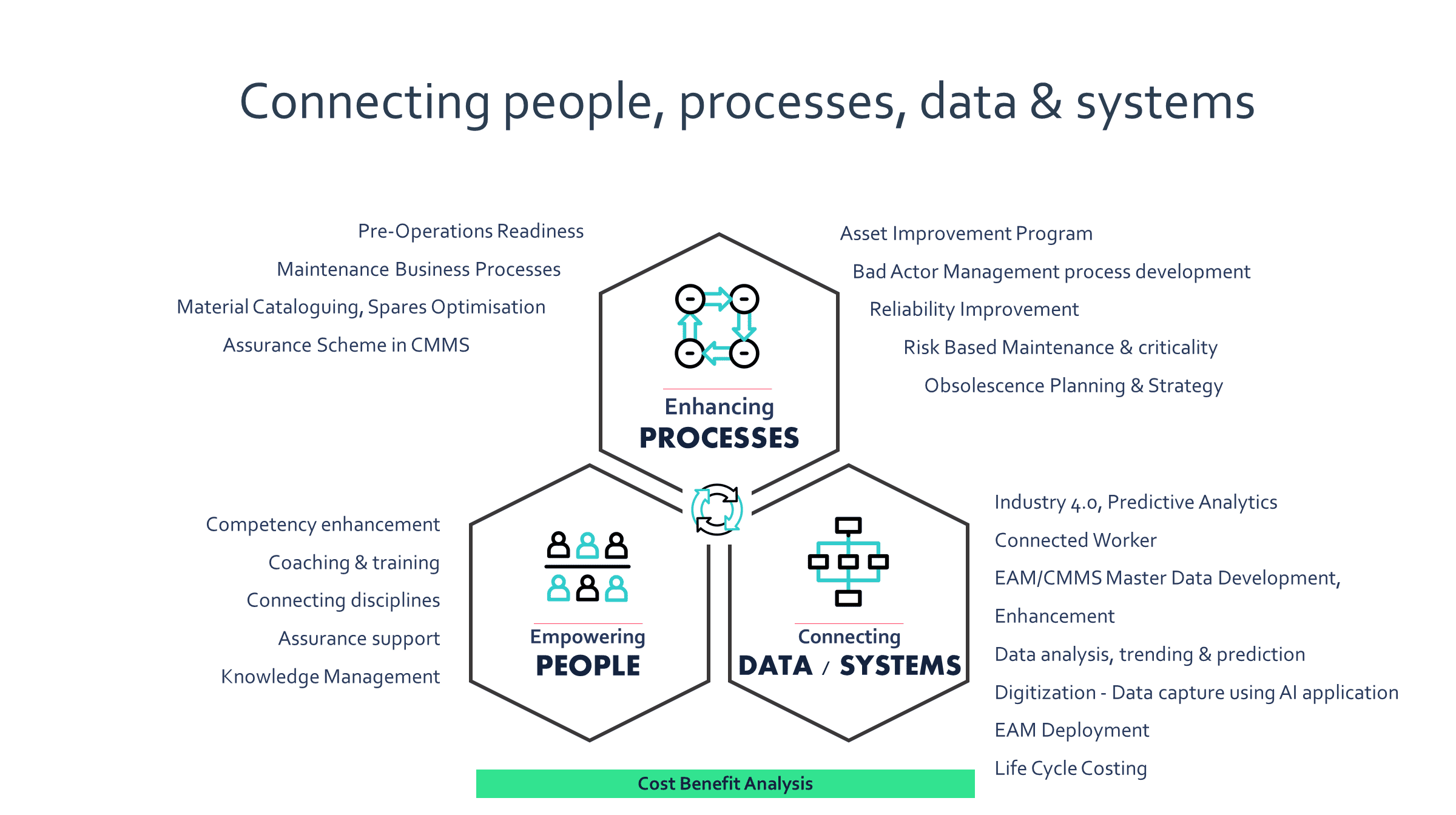

- Holistic and Integrated Approaches: Adopting a holistic and integrated approach across the asset lifecycle can improve asset reliability and safety while reducing costs. This involves connecting data and systems, enhancing processes, and empowering people to use insights to achieve goals. Effective asset integrity management programs address all elements, including processes, people, data, and systems, ensuring control and compliance.

- Asset Life Extension Studies: Performing comprehensive asset life extension assessments can lead to extended asset lifetimes and cost savings. This involves steps like data collection, review and verification, hazards and critical barriers gap analysis, condition risk and life extension assessment, and cost-benefit analysis.

- Continuous Improvement and Cost Optimization: Continuous improvement in asset integrity for multiple offshore platforms has resulted in cost savings and extended asset life. Specialized studies, data dashboarding, and integrity scorecard development are among the key activities that contribute to these outcomes.

To ensure asset integrity effectively, it’s essential to implement a comprehensive strategy that encompasses risk assessment, optimization of maintenance and inspection processes, holistic management approaches, continuous improvement practices, and customized solutions tailored to specific needs and regional requirements. These strategies should be aimed at improving reliability, extending asset life, optimizing costs, and ensuring safety and regulatory compliance throughout.

Is asset reliability the same as asset integrity?

Asset reliability and asset integrity are critical for asset management. In practice, asset reliability and integrity are intertwined; ensuring the integrity of an asset contributes to its reliability, and a reliable asset is often one that is also integral. Both are crucial for the sustainable and safe operation of facilities and for protecting the company’s bottom line, reputation, and compliance with regulations.

Asset Reliability

Asset reliability refers to the ability of an asset to perform its required function under stated conditions for a specified period. It’s primarily concerned with ensuring that assets are available to operate as expected when needed, without unexpected failures or unplanned downtime. Reliability focuses on the performance and efficiency of assets, aiming to minimize downtime and ensure that operations run smoothly. It involves practices like predictive maintenance, reliability-centered maintenance (RCM), and condition-based monitoring to predict and prevent failures before they occur.

Asset Integrity

Asset integrity relates to the ability of an asset to operate effectively and safely, ensuring that it does not pose any risk to health, safety, or the environment. It encompasses the systems, advanced technologies processes, and measures put in place to ensure assets are designed, constructed, operated, and decommissioned in a manner that guarantees structural and functional integrity throughout their lifecycle. Asset integrity management (AIM) involves regular inspections, risk assessments, and adherence to regulatory standards to prevent accidents, leaks, explosions, and other hazardous incidents that could result from the failure of an asset.

Both asset reliability and integrity are aimed at reduced costs and ensuring that assets perform their required functions effectively and as long as required.

What are the key elements of asset integrity?

Asset integrity encompasses various elements aimed at ensuring assets are designed, operated, and maintained safely and effectively throughout their lifecycle. The key elements of asset integrity include:

- Design and Materials Selection: Ensuring asset integrity begins with the proper design and selection of materials that are suitable for the intended operational conditions and the environment in which the asset will operate. This involves using standards, best practices, and engineering principles to ensure that assets are built to last and can withstand operational stresses.

- Construction and Installation: The construction and installation processes must adhere to design specifications and industry standards. Quality assurance and quality control (QA/QC) measures are crucial during this phase to ensure that assets are constructed and installed correctly, eliminating potential integrity issues from the outset.

- Operational Excellence: Operational procedures should ensure that assets are used within their designed operating parameters. This includes proper training for operators, adherence to operating procedures, and the implementation of best practices to minimize wear and tear and avoid operational errors that could compromise asset integrity.

- Maintenance and Inspection: Regular maintenance and inspection are crucial to identify and rectify potential issues before they lead to failure. This involves scheduled maintenance, condition monitoring, and predictive maintenance strategies to address wear, corrosion, fatigue, and other degradation mechanisms.

- Risk Management and Compliance: Identifying, assessing, and managing risks associated with asset operations are fundamental to maintaining integrity. This includes compliance with relevant industry standards, regulations, and laws to ensure safety, environmental protection, and operational efficiency.

- Management Systems: Effective management systems, such as an Asset Integrity Management System (AIMS), provide the framework for integrating all aspects of asset integrity. These systems encompass policies, procedures, documentation, and responsibilities to ensure consistent and effective management of asset integrity.

- Change Management: As operations evolve and assets age, managing changes in processes, technologies, and operational conditions is vital to maintaining integrity. Change management processes ensure that all modifications are assessed, approved, and documented to prevent unintended consequences.

- Emergency Response and Contingency Planning: Preparing for potential emergencies through robust response plans and contingency measures is an essential element of asset integrity. This ensures that, in the event of an asset failure or other incidents, impacts are minimized, and normal operations can be restored safely and promptly.

- Decommissioning and Disposal: Finally, the end-of-life phase of an asset must be managed to ensure that decommissioning and disposal do not pose undue risks to health, safety, or the environment. This involves planning for the safe shutdown, dismantling, and disposal or recycling of assets in compliance with regulatory requirements and environmental standards.

Together, these elements form a comprehensive approach to maintaining the structural and functional integrity of assets, ensuring they operate safely, reliably, and efficiently throughout the design phase of their lifecycle, while minimizing risks to personnel, the environment, and the business.