Enterprise asset management software helps manage the maintenance of an organization’s equipment throughout its asset lifecycle. EAMs assist with everything from asset lifecycle and work order management, to accounting and analytics. Assets can range from buildings to machinery and span across geographies and departments – hence the “enterprise” in enterprise asset management.

Download our best practices checklist to make sure you’re implementing and optimizing your EAM for long term success.

Benefits of using an Enterprise Asset Management system

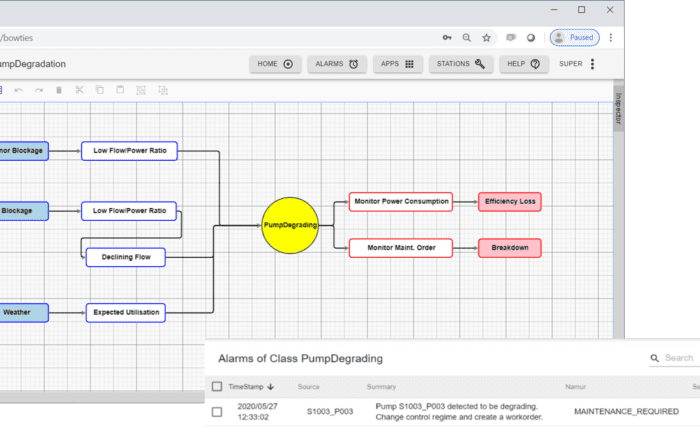

EAMs increase efficiencies for asset management. They eliminate paper-based administration and automate tasks. EAMs not only allow for more efficiencies in collecting and recording asset data, but the automation also offered by customized workflows inside your EAM leads to more standardized and accurate data. Successfully optimizing your EAM provides clearer insights into your organizations finances. EAM software streamlines reports and analytics on the lifecycle of your assets – helping to predict and mitigate costly equipment failures.

Get inspired

NVDO webinar about predictive maintenance and how to put your organization in the driver's seat (webinar in Dutch).

Infographic highlighting the 5 benefits to tracking downtime data.

Evaluating and decreasing TCO is becoming more important as industries mature and look to increase profits by reducing costs.