Introducing MaxGrip’s Asset Improvement Program for physical asset management, our answer to your asset performance challenges. Leveraging years of expertise, we translate these challenges into a customized improvement roadmap and, in the end, lasting performance improvements.

Our clients often approach us to help optimizing their maintenance, reliability and asset management strategies, reducing Total Cost of Ownership (TCO) or overcoming compliance issues. We know that your people are key in sustaining lasting success; our consultants blend domain expertise with experience in change management to get results.

The Concept of (Physical) Asset Management

How is (Physical) Asset Management Defined?

Physical assets represent tangible items or properties of value, owned or controlled by an organization. These assets, which can range from land, buildings, machinery to other tangible resources, play a crucial role in supporting business operations, generating revenue, maintaining, or providing services.

Effective physical asset management in a large organization like oil & gas companies, FMCG multinationals, water companies and manufacturing companies, often involves many different disciplines throughout the life cycle of the assets. This includes maintenance, operations, reliability engineering, management, IT and more. Together, those departments ensure the efficient and responsible use of assets, maintain their optimal condition, and align with the organization’s objectives, ultimately maximizing their value and minimizing associated risks.

Optimizing Asset Performance

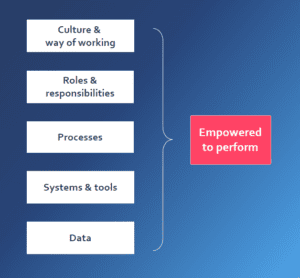

In times of constant change and transformation, performance optimization is crucial. Knowing what your current asset management maturity level is and understanding what your steps can be to get to the next level is important to grow and evolve performance. To be empowered to perform in the best way, five elements are important: data, systems & tools, processes, roles & responsibilities, culture & way of working. The last two pertain to the people working in your organization; they make or break your lasting success.

For an in-depth guide on how to drive performance with asset management, refer to our eBook.

MaxGrip’s Asset Improvement Program

Our program begins with an Asset Improvement Mapping (AIM), a situational assessment resulting in a pragmatic roadmap tailored to your company and endorsed by senior management. Subsequent stages involve the Asset Improvement Deployment (AID), where we help implement changes and prove success, and the Asset Improvement Rollout (AIR), where we support scaling up to standardize and expand results across sites.

For a comprehensive overview, please download this onepager.

Watch Now

The Asset Management Improvement Program in 90 seconds

Asset Improvement Mapping in Seven Steps a Roadmap to Success

What Our Clients Say

“I am satisfied with the traction of the program and the momentum this is generating. MaxGrip is a valuable partner with strong expertise in asset management, maintenance and inspection. The assessments, improvement roadmaps and implementation in the workstreams are proving successful and I see the clear acceptance and adoption by my staff, taking ownership. I am looking forward to the long-term relationship and support from MaxGrip in this excellence program.”

– Jeff Versterre, COO at Victrex –

Frequently Asked Questions About Asset Management

What are Examples of Physical assets in a business context?

Physical assets, often referred to as tangible assets within a corporate context, are imperative to the smooth functioning of any business entity. These assets encompass a broad range of tangible, physical items that hold intrinsic value. They include, but are not limited to industrial machines, assembly lines, forklifts, tools, computer servers, or any equipment necessary for the production process or service delivery. Each one of these elements forms the bedrock of an organization’s operational capability.

What are the Foundational Elements to Successful Asset Management?

A comprehensive and effective Asset Management Strategy is anchored in four fundamental pillars: Data, Systems & Tools, Processes and People. Each of these components interplays synergistically, creating a holistic approach.

A comprehensive and effective Asset Management Strategy is anchored in four fundamental pillars: Data, Systems & Tools, Processes and People. Each of these components interplays synergistically, creating a holistic approach.

- People: The success of any asset management strategy is largely contingent upon the people responsible for its execution. This includes not only the asset managers themselves but also everyone involved in the asset lifecycle – from the employees operating the assets to the decision-makers in strategic roles. Comprehensive training, effective communication, clear roles and responsibilities, a set way of working and fostering a culture of responsibility and ownership are essential for this pillar.

- Processes: The second pillar focuses on implementing robust, structured processes that provide clear guidelines for activities. This involves procedures for tracking and documenting asset status, predictive and preventative maintenance schedules, regulatory compliance, risk management, and end-of-life strategies. Well-defined workflows enable consistency, reduce inefficiencies, and support analytics-driven decision making.

- Systems & tools: The final pillar pertains to the use of advanced technology and asset management software tools designed to streamline your process. These solutions enable precise asset tracking, real-time condition monitoring, automated maintenance scheduling, and analysis. Leveraging technology effectively can dramatically enhance the accuracy and efficiency, ultimately contributing to improved asset utilization and cost savings.

- Data: Foundational data is at the core of informed decision-making. Comprehensive, accurate, and timely data on the condition, performance, and utilization of assets is vital for strategic planning. Data serves to illuminate the current asset condition, ranging from wear and tear to usage rates, thereby enabling predictive and preventive maintenance schedules. Moreover, data can identify patterns and trends over time, leading to insights into lifecycle management and enabling optimization of asset maintenance performance. High-quality data, when properly collected and connected (IT and OT data), organized, and analyzed, drives the ability to optimize asset utilization, mitigate risks, and ultimately maximize the value derived from each asset in line with organizational goals. Effective asset data management is therefore a prerequisite for a successful Asset Management Strategy.

What Includes Asset Management Strategies?

Asset strategies refer to the comprehensive plans and approaches implemented by organizations to effectively manage their assets throughout their entire lifecycle. These strategies encompass various interconnected elements that aim to improve performance, minimize risks, and align practices with organizational goals.

Asset strategies typically include:

- Asset Planning and Investment: This involves setting clear objectives for asset acquisition, end of life, and optimization. It includes developing long-term plans and investment strategies that align with the organization’s overall goals and priorities. Asset planning considers factors such as asset lifecycle, economic value, technological advancements, market conditions, and financial constraints to ensure optimal resource allocation.

- Maintenance and Reliability: This strategy focuses on optimizing performance and reliability through effective practices. It includes implementing preventive and predictive maintenance programs, conducting regular inspections, and utilizing condition monitoring techniques. The goal is to minimize downtime, and maintenance costs, extend asset lifespan, maintain and maximize operational efficiency. For more insights and details, refer to our case study on the Maintenance Excellence Program for Victrex and how it improves sustainability, productivity, and reliability.

- Risk Management: Asset management strategies incorporate risk management practices to identify, assess, and mitigate risks associated with assets. This includes assessing operational, financial, safety, and compliance risks. By proactively managing assets’ risks, organizations can minimize potential disruptions, ensure regulatory compliance, and protect the organization’s reputation.

- Data and Information: Effective asset management relies on accurate and reliable data. Organizations employ strategies for collecting, analyzing, and leveraging asset-related data to inform decision-making and perform asset maintenance. This involves the implementation of systems for data capture, storage, and analysis, as well as utilizing technologies for digital asset management such as Internet of Things (IoT) sensors, enterprise asset management and tracking software, and analytics tools.

- Performance Measurement and Optimization: Asset management strategies incorporate performance measurement metrics and key performance indicators (KPIs) to assess the effectiveness of practices in improving business efficiency. Regular monitoring and evaluation enable organizations to identify areas for optimization, set performance targets, and implement continuous optimization initiatives to achieve them.

By implementing these strategies, organizations can enhance asset life cycles and operational efficiency, reduce costs, mitigate risks, and make informed decisions regarding asset investments, maintenance, and availability. These strategies provide a structured framework for achieving long-term performance, maximizing return on investment, and aligning practices with overall organizational objectives.

Why is Strategic Asset Management Important?

Strategic Asset Management is pivotal as it aligns practices with broader strategic objectives. This structured approach facilitates risk mitigation, financial optimization, and robust decision-making procedure, driving organizational performance, resilience, and sustainability.

What is the Role of Key Performance Indicators (KPIs) in Asset Management?

Key Performance Indicators (KPIs) play a pivotal role in asset management by providing quantifiable measurements that reflect the performance efficiency and effectiveness of assets within a company. They serve as critical tools for tracking progress, identifying areas for improvement, and facilitating analytics-driven decision-making. The specific KPIs employed can vary depending on the nature of the company’s assets and the strategic goals of the business. However, some commonly used KPIs include:

- Downtime: This KPI measures the total time an asset is non-operational due to failure or maintenance. To Minimize and reduce downtime is crucial for maintaining productivity and meeting operational targets.

- Repair Time: Also known as Mean Time To Repair (MTTR), this KPI measures the average time taken to repair an asset after a failure. Shorter repair times typically indicate effective repair procedures and rapid response capability.

- Recurrent Failures: This KPI tracks the frequency of repeated failures for a particular asset. A high rate of recurrent failures may indicate underlying issues that require more than routine repair to resolve.

- Mean Time Between Failures (MTBF): This KPI measures the average time between successive failures for an asset. A longer MTBF generally suggests that the asset is reliable and well-maintained.

One of the most significant KPIs in an asset management process is the Overall Equipment Effectiveness (OEE). OEE is a comprehensive metric that combines availability, performance, and quality to provide a holistic view of asset productivity. It is a critical measure of manufacturing productivity and a key indicator of asset utilization. High OEE scores indicate optimal performance, while low scores can signal potential issues related to equipment availability, performance speed, or product quality.

To illustrate the power of KPIs in asset management, consider the case study of a waste-to-energy plant.

What does Asset Performance Optimization Entail?

Asset Performance Optimization is a sophisticated strategy for your company that seeks to maximize the value and performance of physical company’s assets throughout their life cycle. This concept is at the heart of modern asset management practices, as it focuses on achieving the optimal balance between efficiency, reliability, and cost-effectiveness of asset utilization.

MaxGrip’s Asset Improvement Mapping (AIM) is a methodical approach that evaluates a site’s asset performance management (APM) maturity and its potential for improvement. The AIM process typically spans four to six weeks and serves as the foundational step in optimizing asset performance. This optimization can lead to enhanced production, reduced Total Cost of Ownership, and improved Overall Equipment Effectiveness in the long run.

The AIM approach is broken down into six pragmatic steps:

- Intake & Kick-off: This initial phase involves setting the stage for the entire process, understanding the objectives, and establishing the scope of the assessment.

- Data & Information Collection: In this step, all relevant data and information related to the assets are gathered. This could include maintenance records, performance metrics, and other pertinent documentation.

- Plant Walkdown & Stakeholder Interviews: A thorough inspection of the plant is conducted, and key stakeholders are interviewed to gain a comprehensive understanding of the current state of asset performance.

- Data & Information Synthesis: The collected data and insights from the interviews are synthesized to identify patterns, challenges, and opportunities.

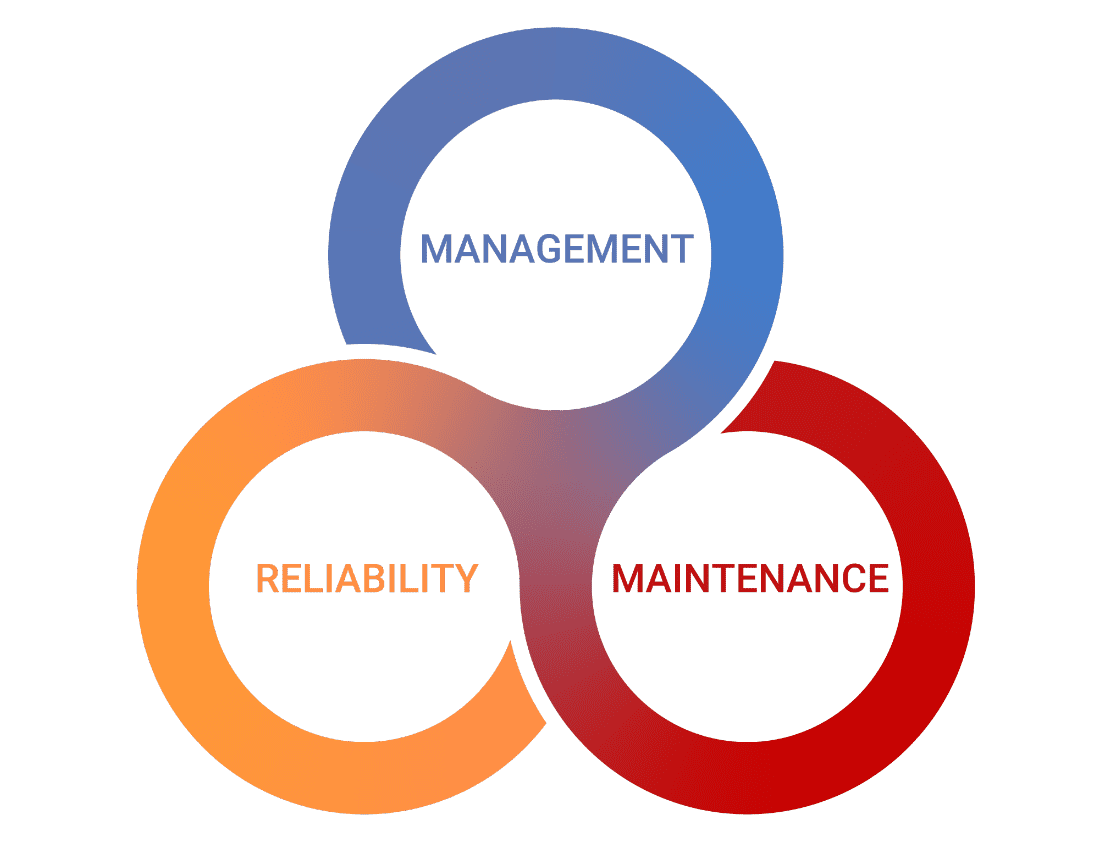

- Improvement Mapping: Using a holistic framework, the dots between maintenance execution, asset reliability, and management are connected. This step assesses the three APM cycles across five areas: culture & way of working, roles & responsibilities, processes, systems & tools, and data.

- Findings, Recommendations & Roadmap: Based on the assessment and mapping, key findings are highlighted, recommendations are made, and a pragmatic roadmap for improvement is developed.

What is the Asset Improvement Deployment?

The Asset Improvement Mapping results in an improvement roadmap that is tailored to the client’s situation and targets, no deployment is exactly the same. The next stage of MaxGrip’s Asset Improvement Program is the Asset Improvement Deployment.

In all deployments we cover the five essential elements of the ability to manage and to improve: Data | Software & tools | Processes | Roles & responsibilities | Culture & way of working

Our consultants are hands-on and work with our clients on various challenges throughout the deployment stage. What happens is highly dependent on the roadmap to improve asset management which is tailored to the site’s needs and maturity level. At a higher level, this means:

- Lower maturity levels: regressive and reactive

Focus on being a well-organized maintenance organization with an eye for robust processes, workflow management, roles and responsibilities. - Mid maturity levels: task optimized and proactive

From maintenance to reliability focus with start of optimization by taking a risk-based approach to asset management. - High maturity levels: proactive and sustainable

Focus on total cost of ownership with TCO as the primary driver for decision-making and cost optimization, digital transformation and long-term planning.

Connecting and aligning people, workflows and systems is pivotal to stimulate change and realize lasting results. At a strategic level we provide program management and coaching to show how to improve workflows and the way of working. We also focus on improving business efficiency and productivity through the use of APM / Industry 4.0 software to demonstrate progress and increased asset performance.

What is the Asset Improvement Rollout?

In the last stage of the Asset Improvement Program we scale up to business assets across multiple sites or plant wide, depending on your company goals. Clients interested in this final stage are typically multi-site companies. Our proven approach for managing and maintaining assets for such organizations includes:

- Clustering of sites based on the estimated maturity level

- One Asset Improvement Mapping performed per cluster

- Improvement roadmap and deployment blueprint tailored to the cluster

- Start deployment with appointed cluster lighthouse sites where site leadership has ownership and MaxGrip coaches

- Embed and sustain: continuous optimization loops for all sites, client in the driver’s seat and MaxGrip’s role scaled back to a minimum.

Meet the Organizations Already Boosting Their Performance with MaxGrip

10 - 15%

Decrease of manpower

25%

Decrease of the backlog