Victrex is a supplier of high-performance polymers and is headquartered in the United Kingdom. It produces polymers, forms and parts for focused markets including aerospace, automotive, electronics, oil and gas and medical. Victrex teamed up with MaxGrip to improve their asset management through a maintenance and engineering excellence program. The new asset management strategy should include the ability to increase output volume and quality, reduce waste and energy consumption. Victrex Senior Management saw potential to further improve capabilities and support ESG (environmental, social and governance) goals.

Challenge: Achieve Maintenance & Engineering Excellence

The Victrex Senior Management team saw the potential for taking the next steps in overall asset performance to further improve capabilities and support ESG (environment, social and governance) goals. The asset management strategy should include the ability to increase output volume and quality, reduce waste and energy consumption, including the ability to monitor and track performance across all sites. All without making any concession to Health, Safety and Environment.

One pillar of this strategy deals specifically with maintenance & engineering.

The objective is to optimize sustainability, availability and reliability with a wellthought through maintenance, inspection and turnaround strategy. This should lead to customer satisfaction and efficiency in use of materials and energy. It should be executed efficiently and should demonstrate compliance. Victrex asked MaxGrip to help with setting up and executing their maintenance excellence program which includes performing a current state and maturity assessment, listing the improvement potential and creating a joined roadmap to meet Victrex’s objectives.

Approach: From Remote Assessment to Deployment with Workstreams

Asset Improvement Mapping

MaxGrip started the project with an assessment, the Asset Improvement Mapping (AIM), on one of the Victrex production units. The assessment includes fourteen essential asset management competencies, related to the three dimensions of asset reliability, overall management and execution of maintenance and inspection. As part of the AIM, MaxGrip interviewed 35 stakeholders across the organization. An AIM typically involves around 25 people, depending on the size of the site. In this case, Victrex asked to expand the stakeholder group in order to scope the potential to do assessments at other plants at the Hillhouse site. These interviews were done remotely due to COVID-restrictions. Additionally, due to these limitations MaxGrip performed the first plant walkdown remotely with Google Glasses. MaxGrip created the proven MaxGrip Asset Improvement Map, using this valuable information, the stakeholder input, the information gathered from data downloads, performance reports and data analyses. MaxGrip engaged with Victrex’s core

team to achieve full alignment and then presented and discussed the findings, and – more importantly – recommended the way forward to Victrex key stakeholders including the COO of the company.

While there was room for improvement, the powder plants also showed best

practices. These included the new asset management strategy, a clear focus

on safety as a first priority, a mitigation process in place for overdue Preventive

Maintenance (PMs) and a promising asset integrity management strategy and

proposals.

MaxGrip’s recommendations included:

- Management: improvement of tracking and monitoring, the creation of a better asset compliance overview and further development of an asset-based OPEX budget.

- Maintenance execution: Improve the work execution optimization loop, use of standard task list library and the development of intake, close-out and reporting standards, maximizing the use of the CMMS system.

- Reliability: set up of Asset Criticality Ranking (ACR), review and update of

PM program and turning the promising asset integrity management proposals into one strategy document and implement it.

These and more improvement recommendations were used for a full currentstate maturity mapping and improvement roadmap. These actions created a target setting per Asset Performance Management (APM) competence. The implementation of these recommendations will see Victrex progressively improving their maintenance excellence with an effective, globally scalable approach and at a pace which matches the capability of the organization.

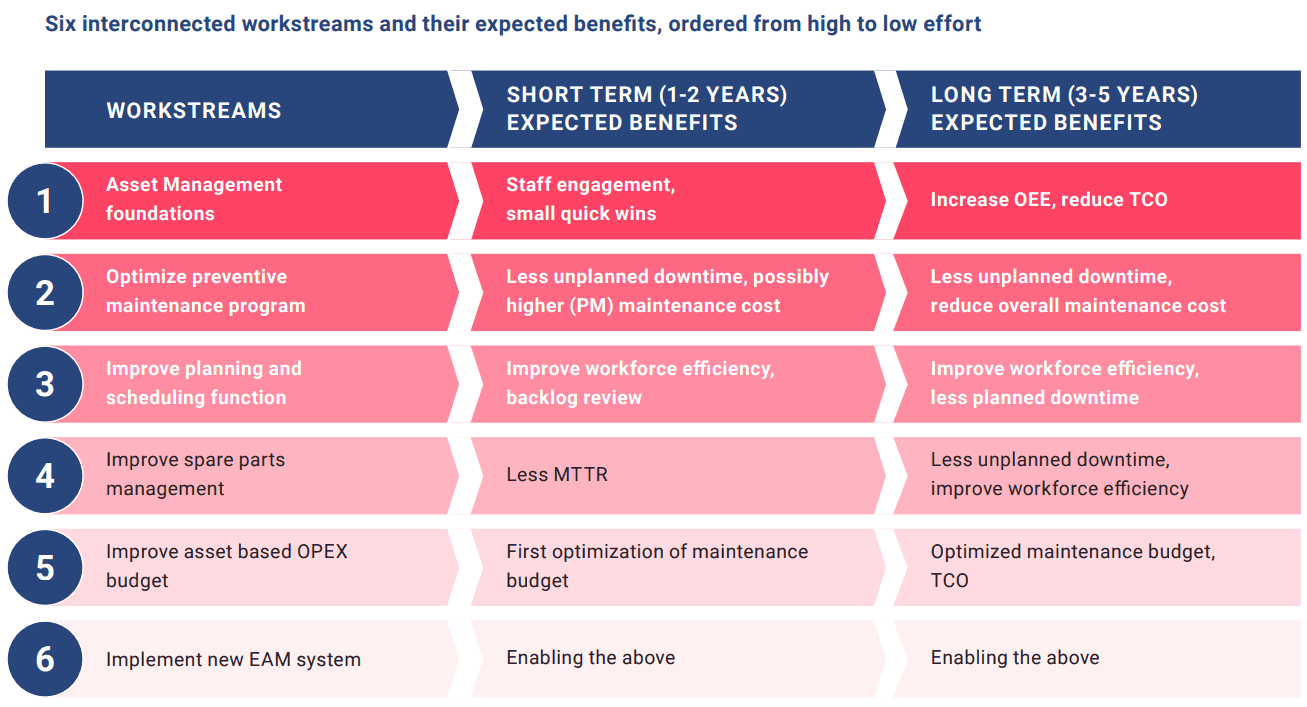

Deployment in workstreams

The next step is the first one for a deployment, also called an Asset Improvement

Deployment (AID). This entails the further detailing of an improvement roadmap,

the planning and deliverables. The AIM has provided a first high-level with which

our client takes over the lead. They are supported by MaxGrip consultants with

their experience and insights also from other projects and comparable clients.

Victrex demonstrated their ability to take ownership and create the Asset

Improvement Deployment program (AID), together with MaxGrip. The deployment

was split up in different workstreams, all owned by Victrex Leads with named

owners to lead each workstream and individual workstream objectives, as well

as the overall coherence and interdependencies:

0. Program management

1. Asset management foundations

2. Optimization of preventive maintenance program

3. Development of planning and scheduling

4. Improvement of spare parts management

5. Set up of asset based OPEX budget

6. CMMS (EAM) – introduction of a new and common Enterprise Asset

Management system across all sites

What followed was a site visit and a number of workshops in which the workstream

leads worked together with MaxGrip staff to refine their workstream business case,

their specific goals, detailed planning and required resources, skill sets and time.

The workstream leads presented their plans to the COO and in a meeting with all

of the leads and MaxGrip together, it was decided to start with four workstreams

(in bold above). These workstreams are seen to be fundamental to realizing

asset performance improvements across the plants already in the short term.

The streams also influence and have essential inputs to the other three streams,

which justifies starting with these four.

The four workstreams with which we started:

- Program Management

This runs through and oversees all of the other workstreams and safeguards

project management and change management. This includes setting up

the governance of the overall program, alignment of project activities, the

communication and engagement plan as well as the progress tracking and

monitoring of all projects. - Foundations

This consists of the development of an asset management foundation

structure (global), the development of the Long-Term Asset Planning (LTAP)

process, finetuning of the overall maintenance strategies, redefining roles and

responsibilities, required capabilities and deliverables, as well as the development

of Asset Integrity Management strategy with associated tracking and tracing. - Optimization of preventive maintenance program

Some of the core elements of this workstream are: performing and updating asset

criticality rankings, the development of Preventive Maintenance (PM) standards,

the review and optimization of the PM program, measuring PM effectiveness. - CMMS/ EAM

This workstream focuses on introducing a better and common CMMS (Enterprise

Asset Management (EAM) system. Victrex realized that a sustainable improvement

could only be achieved by having an EAM system which would fill essential gaps

in the current system. This not only implied to set up a very clear requirement

specification, but also to map out the business processes and functional interfaces to other systems and disciplines. It also includes the creation of a so-called common data standard (taxonomy) configuration of the EAM system. Moreover, it entails the creation of a balanced and realistic EAM roll-out plan, not affecting current production, training and familiarization of the users, data cleansing etc. Relevant reports are being created and validated to be able to monitor and steer actual asset performance improvements, as set out in the initial plan.

“I am satisfied with the traction of the program and the momentum this is generating. MaxGrip is a valuable partner with strong expertise in asset management, maintenance and inspection. The assessments, improvement roadmaps and implementation in the workstreams are proving successful and I see the clear acceptance and adoption by my staff, taking ownership. I am looking forward to the long-term relationship and support from MaxGrip in this excellence program.”

– Jeff Versterre, COO at Victrex –

The Results: Solid Long-Term Benefits Expected

The deployment of the workstreams is underway. Victrex is focused on the long term

and has set up a solid deployment structure with the workstreams. Progress tracking

is running, and re-assessment of the performance improvement progress will take

place soon. Some preliminary and projected results:

- The program will result in an overall sustainable performance improvement. This

reduces costs and improves reliability resulting in lower costs of energy and waste.

Actual results are tracked against projected multi-million pounds cost savings. - The AIM assessment and AID deployment with resulting workstreams have served

as the blueprint for global scale up, with Victrex integrating the road to excellence

in their own operational model (MaxGrip calls this the Asset Improvement Rollout). - The focus, right from the start, on Victrex taking ownership and dedicated attention for change management to bring and keep people on board, as well as proper project management have proven to be essential for a sustained, multi-year change program.

OEE = Overall Equipment Effectiveness, TCO = Total Cost of Ownership, MTTR = Mean Time To Repair

Get inspired

This article provides an overview of MTBF and outlines how to use this knowledge to calculate, improve, and use these metrics for building KPIs.

In the first half of 2022, MaxGrip organized a Round Table on the topic of Data Driven Asset Management. It was attended by ten maintenance and operations managers from leading companies like Heineken, Abbott Nutrition, Waternet, Vopak and Smurfit Kappa Parenco.

Ontdek de kracht van verandering in ons webinar met Willem van Keulen. Leer essentiële change management-strategieën en krijg nieuwe inzichten.