Over a 4-month period, MaxGrip supported a building materials manufacturer as they transitioned from a legacy EAM to a new solution. This guidance led to an increase in workforce efficiency, improved data capturing, and a successful EAM adoption across the entire organization.

About the Client

MaxGrip’s client manufactures commercial and residential building

materials. They are headquartered in North America and have operations

which extends across 60 facilities.

Recent changes within the organization required transitioning to a new

Enterprise Asset Management (EAM) solution as their legacy EAM no

longer met their needs.

They sought MaxGrip’s guidance to use this transition as an opportunity

address additional areas of improvement within their organization.

The Challenge

The client desired to use their new EAM solution to help them address

several improvement areas across their maintenance department that

were impacting their day-to-day operations, including:

- A complex EAM system that was incompatible for their site

- No training program or documentation of processes

- Inconsistent maintenance data capturing and reporting

- Inaccurate foundational data

To overcome these challenges, the maintenance supervisor and planner

had to take on a higher administrative workload in addition to their

operational responsibilities.

The Scope

To begin the project, MaxGrip performed an Asset Improvement Mapping

(AIM), which created a roadmap to directly address the challenges they

were facing. This roadmap would help ensure the transition was both

efficient and seamless to minimally interrupt business operations.

MaxGrip provided the client with a scope that included:

- Phasing out the legacy EAM with business continuity

- Building a training program

- A strategic, guided EAM transition

Our Solutions

Phasing out the legacy EAM with business continuity

Over a 4-month period, MaxGrip guided the client through internal

facilitations which included several critical departments such as

maintenance, production, engineering, IT, and corporate leadership.

These facilitations ensured there was a clear alignment in objectives

between the business and its operational activities. It also provided the

opportunity to establish what the goals and key performance metrics were

for the entire organization.

Once all stakeholders were aligned and onboard, the necessary steps were

taken manage, update, and migrate their asset data in a way that ensure

business continuity.

Building a training program

A key part to ensuring long-term success and alignment is to ensure

that there is a program in place to continue to support EAM training and

continuous improvement between EAM workflows and maintenance

operations and work processes.

Strategic, guided EAM implementation

The MaxGrip team supported the deployment of their new EAM solution

across all phases of the project, which included:

- EAM system testing & debugging

- Operations workflow integration

- Master data management

- Training & employee coaching/support

- Developing KPIs and a system for tracking

- Go-live and post-implementation support

- Ensured business continuity

The Results

MaxGrip’s guidance helped the client meet their tight transition deadlines

and EAM usage desires.

Improved workforce efficiency

Since the EAM’s data management was now dispersed across a team

of technicians, it contributed to a decreased administrative load on the

maintenance supervisor and planner. This allowed them to focus their

internal resources on operations.

Increased EAM usage

By integrating training and workflow within the EAM, the client’s

maintenance team was able to exponentially improve their knowledge of

the tool and, therefore, increase its adoption.

Clean and usable data

As part of the implementation of this new EAM, the client’s asset data

(including asset hierarchy and maintenance plans) were updated and

produced improved data capturing and reporting.

Data management tools

As part of the implementation, MaxGrip helped to integrate new data

management tools. These tools allowed the client to use their EAM data

to help drive their maintenance strategy, increase operational efficiency,

and improve their asset reliability.

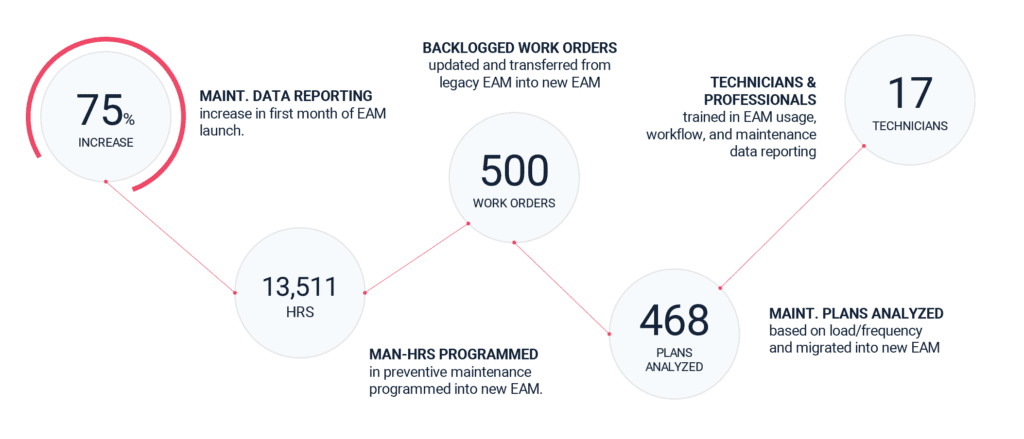

Results in numbers

Get inspired

On December 19 of 2022, it is exactly 25 years ago that MaxGrip was officially founded. We asked Jakob Boelens, one of our founders and senior partners of the company, to share his top five of 25 years in business.

Scaling up digital transformation initiatives come with a set of business challenges. In this webinar we discuss those challenges with LNS Research.

Infographic highlighting the 5 benefits to tracking downtime data.