Mean Time to Repair (MTTR) is a reliability metric that helps calculate how long it takes to restore an asset to its operational capabilities.

Our second article on Reliability 101 covers MTTR – its importance, how to calculate it, and factors that influence the results.

Key Takeaways

- Mean Time to Repair (MTTR) measures the average time needed to restore an asset to its fully operational capabilities.

- The formula for MTTR calculation is Total Repair Time (in hours) / Total Number of Failures

- The only way to accurately measure MTTR is by using a CMMS or EAM with proper workflow and timestamps that collects data from multiple sources.

- MTTR can provide valuable insights that drive your organization’s maintenance and reliability strategy.

- MTTR is different from Mean Time Between Failure (MTBF). MTBF is a statistical measure of the probability of an individual component failing before reaching the end of its service life, while MTTR focuses on the time it takes to restoring its functionality after a failure.

- Ways to reduce MTTR include building internal processes that avoid unnecessary delays, improving the speed of diagnosing and reporting a failure, developing maintenance plans for critical assets, and having a critical spare parts and equipment plan.

A key part to effective maintenance planning is implementing the right tools and processes to track performance. A common way to achieve this is by using reliability metrics to measure performance, identify areas of improvement, and validate the effectiveness of maintenance activities.

In this article we take an in-depth look at Mean Time to Repair (MTTR), a frequently used reliability metric that helps track maintenance efficiency, and how it can be used to influence an organization’s maintenance and reliability strategy.

What is Mean Time to Repair (MTTR)?

Mean Time to Repair (MTTR) measures the average time needed to restore an asset to its fully operational capabilities. It is an essential measurement of an asset’s maintainability.

MTTR is also helpful in assessing the effectiveness of an organization’s maintenance plans and procedures. It helps understand how long it will take to repair or replace an asset and whether that downtime makes sense for cost-of-ownership and continuity.

How to calculate MTTR

Mean Time to Repair is calculated using the following formula:

MTTR = Total Repair Time (in hours) / Total Number of Failures

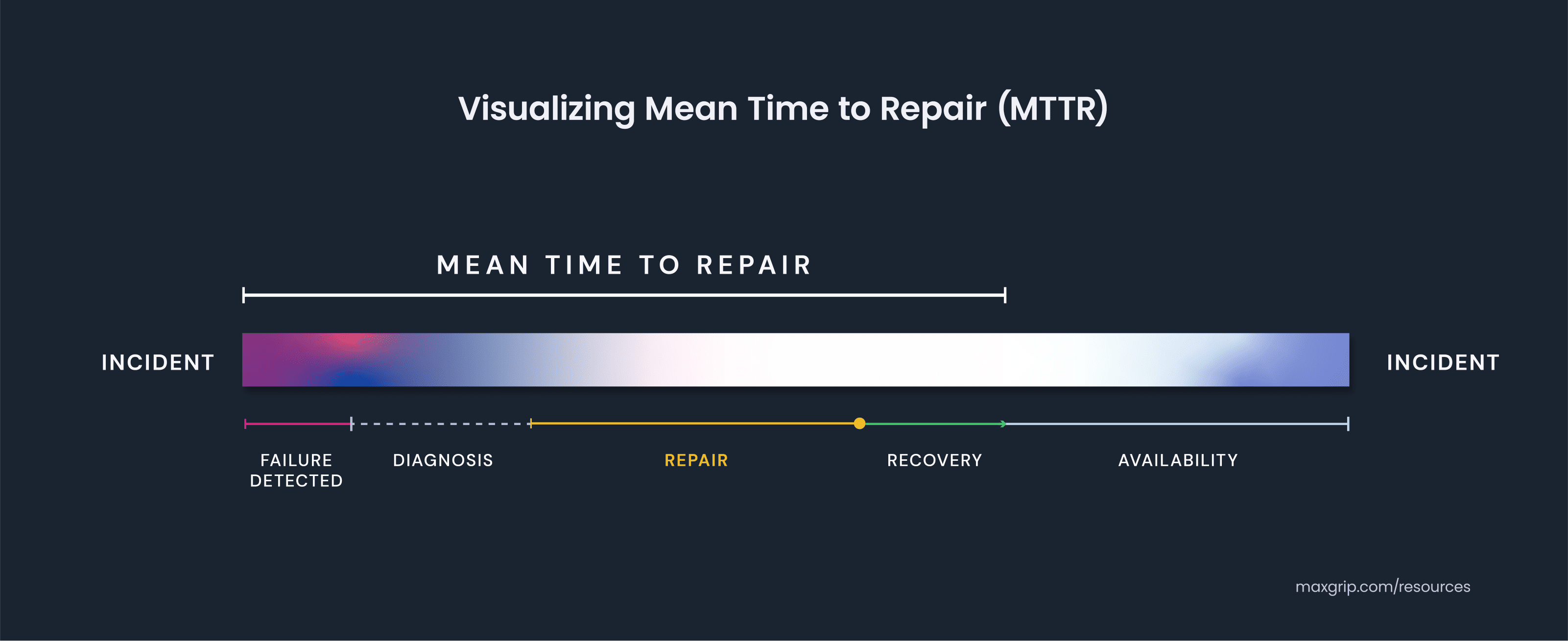

Repair Time is the time needed to restore an asset’s function after failure by repairing or replacing equipment. It begins when the asset stops running to the time its operation is restored.

Failure is when an asset or component cannot meet its expected performance. It does not always mean that the asset is inoperable, simply that it is not meeting operational or quality requirements.

An excellent way to accurately measure MTTR is using a maintenance management system (CMMS, EAM, or APM) with the proper workflow and timestamps to collect data from multiple sources.

An example workflow looks like this:

- An operator enters a correctly coded work order,

- A planner releases the work order,

- A technician adds their time to the work order, and

- The work order is closed on time

You would then use this data to develop historical trends and pinpoint the patterns contributing to an extended MTTR.

What MTTR results mean

A higher MTTR indicates a high failure to functional recovery time for an asset. Generally, this tells you there are inefficiencies within the repair process or the asset itself. A high MTTR for a single asset may indicate that more workforce training is needed to troubleshoot and repair, or it could simply mean that the asset has reached the end of its useful lifecycle.

A lower MTTR means that failure to recovery time is faster, more efficient repair time and, therefore, would indicate a healthy maintenance process.

Benefits of MTTR

Mean Time to Repair (MTTR) is an important reliability metric that can provide valuable insights into an organization’s maintenance and reliability strategy. Through measuring the average time needed to restore an asset to its operational capabilities, organizations can identify bottlenecks and potential areas of improvement, spot downtime trends, and predict future events. Furthermore, reducing MTTR can result in reduced operational costs and improved efficiency, allowing organizations to optimize their maintenance programs and achieve operational excellence.

How Mean Time to Repair is different from Mean Time Between Failure

Unlike Mean Time Between Failure (MTBF), MTTR is not a direct indicator of the number of failures an asset experiences over its lifetime. Instead, it reflects the average time it takes to recover from a failure.

MTBF is a statistical measure of the probability of an individual component failing before reaching the end of its service life. The longer the MTBF, the less likely any component will fail during its service life.

How Mean Time to Repair different from Mean Time to Recovery

Mean Time to Recovery is similar to Mean Time to Repair but focuses on the time it takes to recover an asset after a failure instead of restoring its functionality.

The difference between these two measurements is that Mean Time to Recovery includes all failures, while Mean Time to Repair excludes those that result in the asset being taken out of service.

Ways to reduce MTTR

In addition to being able to calculate MTTR, you should also know what factors affect it and how these can be improved to reduce the response time and the amount of time it takes to repair an asset. Here are some of the critical variables that influence MTTR.

Building internal processes that avoid unnecessary delays

Diagnosing the cause of an asset failure can often be the source of many delays and can impact operational time, directly affecting production. It even impacts customer satisfaction.

To decrease repair time, creating a culture where everyone understands what must happen before something goes wrong is highly important. You should establish clear roles and responsibilities within the maintenance team and assign members to specific tasks. Make sure that they know when others are working on another project.

If failures are not adequately tracked and documented, this can lead to inaccurate estimates of MTTR. Therefore, setting up an effective communication channel between the teams responsible for repairs will help to facilitate and speed up the diagnosis process and narrow down the failure’s cause.

Improving the speed of diagnosing and reporting a failure

What is the current process in place if a critical asset fails?

Is it fast enough to get the problem fixed quickly? If not, how do you plan to improve it?

Do technicians have a complete picture of the asset’s documented and standardized history? Is there a system in place (i.e., a CMMS or EAM system) to serve as a central hub for this information?

A CMMS or EAM will help with diagnosing and reporting by keeping track of:

- The history of maintenance tasks performed,

- Previous failures and how they were resolved, and

- The location of replacement parts and components

An efficient diagnosis and reporting system will make equipment recovery more efficient for the technician, reducing the time needed to restore the asset to functional operation. For some teams, MTTR functions as a way to develop and keep track of Key Performance Indicators.

Developing maintenance plans for critical assets

A common cause for a high MTTR is not planning for the eventual failure of an asset until it is too late. Developing a maintenance program early on is a crucial method for reducing the extended downtime of an asset.

For example, condition-based maintenance is a strategy that uses statistical analysis to pinpoint and remedy potential problems before they become serious issues, thereby reducing the amount of time that it is down. It also helps to ensure that your organization does not spend more time or money fixing equipment that no longer has value.

A critical spare parts and equipment plan

For an organization to perform emergency repairs, it must always have a plan for which critical spare parts to store.

A bill of materials, or a list of the items necessary to support the operations and maintenance of an asset/component, will help to quickly show which components or spare parts are needed during emergencies and when replacements are due. This planning will ensure that normal operations continue uninterrupted, even during unplanned downtime.

The storage and proximity of these critical spares should be considered when creating this plan. For example, if the reserves are stored far away from the site, reaching the facility in an emergency would take longer. Therefore, having a close-by storeroom makes sense as it would speed up the repair process. Review the best practices for MRO and spare parts in our on-demand webinar.

How MTTR can influence an organization’s maintenance strategy

Aside from measuring how long an asset takes to go from down to fully operational, MTTR can provide helpful insights that will influence and drive your organization’s maintenance and reliability strategy.

Measure the maintenance program’s effectiveness

MTTR is an excellent metric to assess the maintenance processes that directly contribute to the speed of your site’s recovery process. This information helps to spotlight inefficiencies in the process and can inform improvement plans.

Pinpoint bottlenecks

Knowing which components require the most prolonged time to recover can pinpoint areas where improvements may yield results. For example, suppose a piece of equipment has been experiencing frequent outages, but its MTTR remains low. In that case, chances are that the issue lies with the maintenance processes in place rather than the actual asset.

Influence asset investment strategy

MTTR analysis can help you make better decisions about how to spend money on assets by identifying those that will benefit the most from upgrades. While this is not the single way to determine the best investment, you can use MTTR combined with other reliability metrics to establish the decision-making criteria when making these decisions.

For example, if a machine requires constant monitoring and repair, but the cost of repairing it exceeds the value of the machine itself, it would be more beneficial to invest in a replacement rather than a repair. On the contrary, if the same machine only experiences occasional issues, investing in additional resources could be counterproductive and wasteful. A helpful method for making this actionable is Reliability Centered Maintenance, a structured maintenance approach that helps develop an efficient and effective maintenance strategy to minimize the probability of failures.

Spot downtime trends and predict future events

Using data collected through an MTTR analysis, you can spot patterns and predict future events. If you notice that certain types of machines consistently experience elevated levels of failure, you can use this knowledge to improve preventive measures. This reduces the work needed to address breakdowns later down the line.

The technique used to examine an asset, process, or design to determine the potential ways it can fail is known as a Failure Mode and Effects Analysis (FMEA).

Reduce operational costs

An effective maintenance program reduces unnecessary repairs, which means fewer work hours, overtime, supplies, and materials costs associated with maintaining the asset. These savings can be substantial over time and can be used to fund more maintenance projects.

The value of this knowledge can go a long way.

Beyond a single reliability metric

MTTR is a valuable tool to measure the effectiveness of an organization’s maintenance plans and procedures. However, MTTR is one of several metrics to calculate reliability. Although not all metrics apply universally, they can be the basis for reviewing maintenance processes and achieving operational excellence.

Another helpful metric we briefly covered is MTBF, which lets you know how long an asset or equipment will run before it experiences a failure. Read more about this valuable metric here.

🖥 Watch On-Demand: Foundational CMMS data

📰Continue Reading

- Using Data Insights to Strengthen Your Organization’s Maintenance Strategy

- How business context can influence asset performance benchmarks

- Reliability Metrics: Mean Downtime (MDT)

- Infographic: 5 Benefits of Tracking Equipment Downtime

- How to build a Preventive Maintenance program for long-term success

- Checklist Preventive Maintenance vs Predictive Maintenance

Get inspired

Checklist with best practices to keep in mind when planning your asset life extension (ALE) process.

The number one hurdle to make digital transformation successful? According to 62% of business leaders it is organizational culture (as reported by MIT Sloan and Capgemini). This widespread challenge drives home the message that your company culture needs to be a key element in your industry 4.0 change strategy.