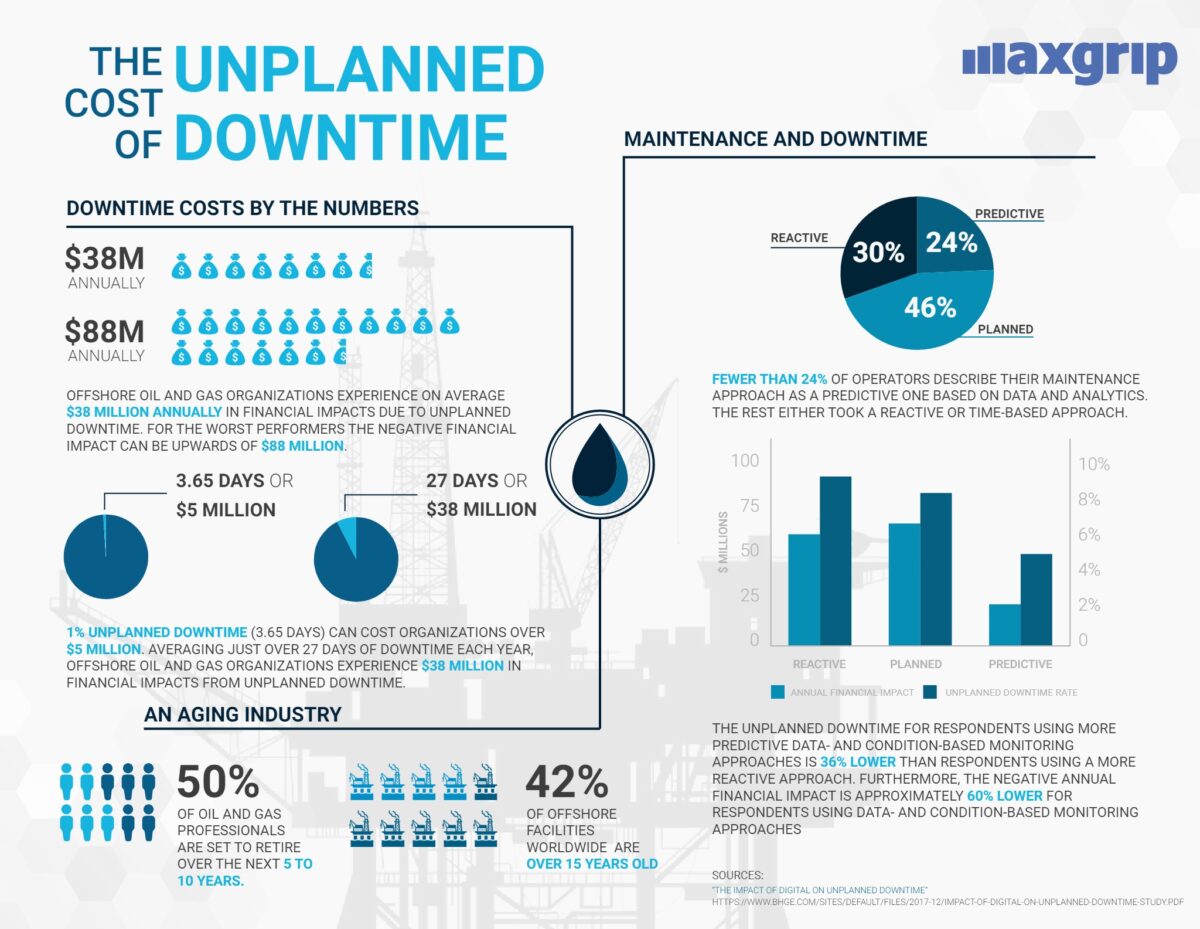

The negative financial impact of unplanned downtime in the oil and gas industry adds up to tens of millions every year. Even a 1% unplanned downtime adds millions in maintenance costs and lost production. Download our infographic to see the numbers behind unplanned downtime.

Maintenance Approaches Affect Downtime

Despite the large financial impact unplanned downtime can inflict, few oil and gas organizations utilize optimized maintenance strategies. Discover how data is crucial for shortening unplanned downtime and why predictive maintenance can be a useful tool to limit the impact of downtime.

Get inspired

NVDO Webinar about getting your APM data in order (in Dutch).

Vitens and MaxGrip host a webinar in Dutch on data driven maintenance, their process and learnings. Collaboration with the Dutch maintenance organization NVDO.

Download our whitepaper to learn the key insights for implementing a successful preventive maintenance program.