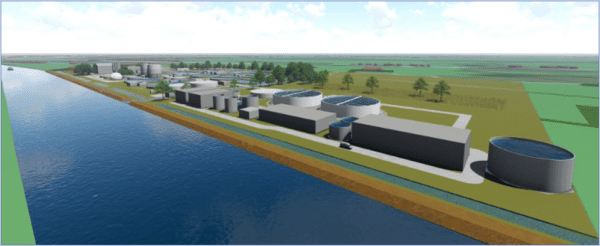

The industrial zone of the Eemshaven (in the Netherlands) has been undergoing considerable expansion in recent years. This means an increasing water demand from Northeast Groningen for industrial water to use as cooling and process water. In order to preserve precious groundwater as a source for the drinking water supply, surface water from a canal is used as cooling and process water.

Due to the expansion projects in the area a new 28-kilometer long water pipeline from Garmerwolde to the Eemshaven is planned to keep up with cooling capacity demand. The new installation is commissioned by the consortium North Water, a joint venture between Evides Industry Water and Water Company Groningen. They asked MaxGrip to support a Failure Mode and Effects Analysis (FMECA) study on the design to ensure reliability of the assets.

Case study – highlights

Approach

The industrial water treatment installation is designed to deliver 10 million m3 industry water per year. The yet to be built installation will consist of, amongst other things: four intake pumps, three parallel purification lines, six double-layered filters, two transport pumps and four chemical areas. So, the objective of the FMECA was to timely identify potential failure, to assess associated risks and to advise preventive actions for these assets.

The design FMECA that we performed investigated the risk of technical failures of the preliminary design of the plant, assessed the preliminary design against the performance and reliability requirements and served as advice on required design changes and preventive maintenance focus points. The scope of this study encompassed 140 units and 900 components.

By using this approach, we had enough information to do a design FMECA on the preliminary design, to determine essential improvements to the final Piping and Instrumentation Diagrams (P&IDs), and to identify the risks and necessary alterations to the design as well as determine what components will need preventive maintenance to offer full availability and reliability of the installation.

Results

The results can be split up into three categories.

- Design modifications and focus points for preventive maintenance

With this design FMECA, we were able to detect critical failure risks in time to be able to change the design and appoint focus areas for the preventive maintenance program and thereby ensuring the reliability of the installation. - Optimization of plant breakdown structure and tagging

Because the design FMECA was an extra ‘dry exercise’ at the unit level before implementation in the asset management system, it offered the opportunity to change the plant breakdown structure where needed. - Knowledge transfer

Another result is that due to the structured way of working in a multidisciplinary group, different experts from the collaborating companies Evides Industry Water and Water Company Groningen were able to share a lot of knowledge, connect and collaborate more strongly on this joint project.

Get inspired

Learn about RCM, how it can streamline your maintenance operations, and why it’s a powerful strategy to lower maintenance and reliability costs.

Verdantix, an independent research and advisory firm, has designated MaxGrip as the innovator in the 2024 Green Quadrant for Industrial Asset Management Technology Implementation Services.

MaxGrip's strategic approach to asset management maturity involves aligning organizational goals, enhancing data and system integration, and emphasizing process efficiency and human resource empowerment for effective and continuous improvement in asset performance management.