The ability to realize improvements in asset management is a journey that goes hand in hand with your ability to learn and grow. The first step in making step-level changes in your maintenance maturity is having a full understanding of the current maintenance maturity level. Knowing where you are and where you want to be is critical for building a pragmatic improvement road map. This article explores the importance of understanding a site’s maintenance maturity, how this impacts strategy and goal setting, and identifying the building blocks to getting started on the road to improving asset performance.

Maturity Levels and Focus

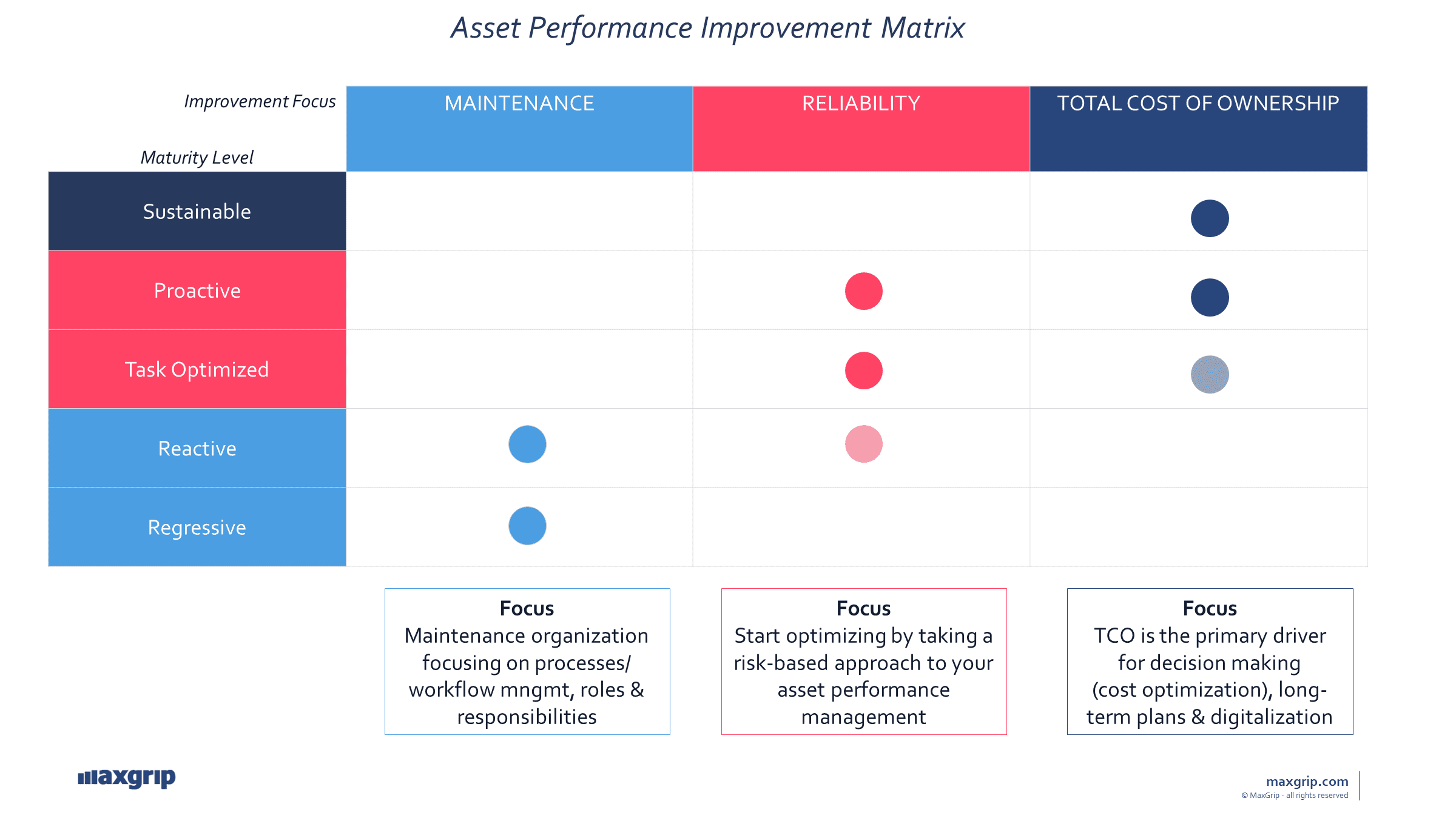

There are five maturity levels for maintenance and asset management: the lowest levels are regressive and reactive, the middle column includes task optimized and proactive, whereas the top tier is the sustainable level. Knowing at which level the maintenance department operates is the right start for improvement. Realistically speaking, a company at a reactive level should have a different focus and other improvement ambitions than a company at the proactive level. Those goals and improvement opportunities need to align with the organization’s goals and its business context. However, the overall focus can be described in the

Figure 1 maturity matrix. In other words, realizing change and improvements in maintenance, reliability and asset performance can only happen if you have realistic growth ambitions.

Current State Assessment

Assessing the maturity level of the current asset performance management is a process that should be holistic, meaning that it includes information, data and insights from management, maintenance and reliability perspectives. Best practice assessments include information, such as strategic plans, key performance indicator (KPI) reports, organizational charts, workflow processes, asset registries, computerized maintenance management system/enterprise asset management system (CMMS/EAM) historical data, preventive plans, financial data and more. Additionally, a plant walkdown and stakeholder interviews provide valuable input. Based on these inputs, an improvement assessment results in recommendations that are a starting point and serve as the input to develop a road map to get

improvements realized and to take the next step in maturity growth.

Best Practice Building Blocks

Taking the step from insights to actions is always a big one. Being empowered to perform and improve entails four building blocks: data, systems, processes and people. Let’s have a look at these building blocks and share some best practices of companies, taking a reactive maturity level as a baseline.

Data

A solid data foundation and effective sustainable data management practices are key elements to accurate and complete data that can be utilized to gain insights for decision-making purposes. Having accurate and tangible data is essential to gain and keep control over your asset-based budget (i.e., operating expenses or OPEX). Companies that have a reactive maintenance maturity are usually not entirely in control of their data, which leads to incomplete data sets. This, in turn, provides little to no insight into current opportunities. Master data has to be complete, up-to-date and connected. This includes setting up a robust asset hierarchy and performing an asset criticality ranking, which will then improve the preventive maintenance/corrective maintenance (PM/CM) ratio. That is typically a big win at this maturity level.

Systems & Tools

The right systems provide a means to organize, manage and interpret the vast amounts of data that a facility typically deals with. An essential one is the EAM system, as it is used to manage and control the maintenance workflow to have efficient planning, preparation, scheduling and execution of work orders. Your EAM system is an enabler to facilitate people to do their jobs efficiently by establishing sustainable, repeatable processes that remove bottlenecks and meet industry best practices The EAM system, furthermore, allows you to measure progress and improve asset performance based on set KPIs. Optimizing the use of the EAM system boosts maturity growth significantly.

Processes

Reactive maturity level companies typically have some poorly defined or outdated workflows that create inefficiencies that could lead to unsafe situations. Workflows are crucial because they bring structure and consistency to your operations. When improving asset performance management and maintenance, processes also should be updated to match the new way of working. This includes updating and optimizing workflows in the EAM system.

People

This is the most important building block of all because people are pivotal to realizing change. The people in your team are the ones implementing your systems, following processes and analyzing the data. Their skills, knowledge and attitudes can significantly impact the effectiveness of your asset management strategy. Give the workforce ownership of the improvement road map and make sure roles and responsibilities align with the expectations. Engaging them in process improvements, encouraging them to contribute ideas, training and coaching, and fostering a culture of continuous improvement are all factors that have proven to be effective in accelerating maturity growth and performance optimization.

Conclusion

Enhancing asset performance requires understanding your maintenance maturity level and setting realistic goals and ambitions. Leveraging all building blocks – data, systems, processes and people – is crucial for success. While all building blocks are important, people are pivotal. By empowering people and fostering a culture of continuous improvement, organizations can achieve significant growth in maintenance maturity and optimize asset performance.

Katherine Sanchez

Katherine Sanchez is a maintenance and reliability professional with over 12 years of experience in operations, engineering, asset reliability and continuous improvement. She has developed business continuity plans for operational, maintenance and management teams. Additionally, she has established asset care programs for multiple industries, focusing on failure mode and effect analysis (FMEA) and reliability-centered maintenance (RCM). She also has hands-on experience in implementing and deploying EAM systems. Katherine is a managing consultant at MaxGrip, which is a consultancy firm specializing in asset performance management.

Get inspired

MaxGrip senior consultant Niek Dillerop presented a client case during the IFS Ultimo Software Solutions conference.

We explore how proper data management can lead to significant increases in equipment updates and reduce overall inventory carrying cost.

How will digital transformation take form for industrial companies and how will it transform asset performance management?