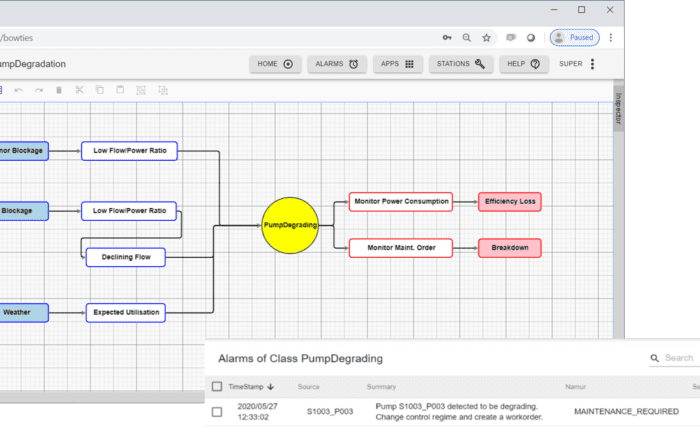

Root cause analysis is an important part of doing business in any organization that strives toward continuous improvement, increased risk management, and greater reliability through methodologies or principles such as kaizen, Deming PDCA cycle, Six Sigma, poka-yoke, or Lean. The RCA process can take the form of Ishikawa (fishbone) diagrams, 5 Why’s, Apollo, RATIO, and more but always maintains focus on identifying the primary cause(s) behind an unexpected or undesired outcome that may exist among a multitude of chain reactions, contributing factors, and secondary symptoms of the problem in order to eliminate, reduce likelihood of, or reduce impact of recurrences.

Watch the webinar

Fill out the form below and you’ll get access to the webinar recording.

What you’ll learn in this webinar

Presenter: Katrina Brandenburg

Maintenance & Reliability Consultant

Katrina Brandenburg has worked in a variety of roles in the oil & gas and chemicals industries since 2013 before transitioning into maintenance & reliability by way of mechanical integrity – specifically risk-based inspection. Recently, she’s worked as a reliability engineer, consulting on projects for RCM, RBDs, and RAMS studies.

Get inspired

Middle managers are the driving force for effective change. We list three essential ingredients.

NVDO webinar about predictive maintenance and how to put your organization in the driver's seat (webinar in Dutch).

Join MaxGrip for an enlightening webinar on "Asset Management Technology Implementation," featuring Verdantix. Wednesday, May 22nd, starting at 4 PM CEST | 9 AM CDT. Don't miss it!