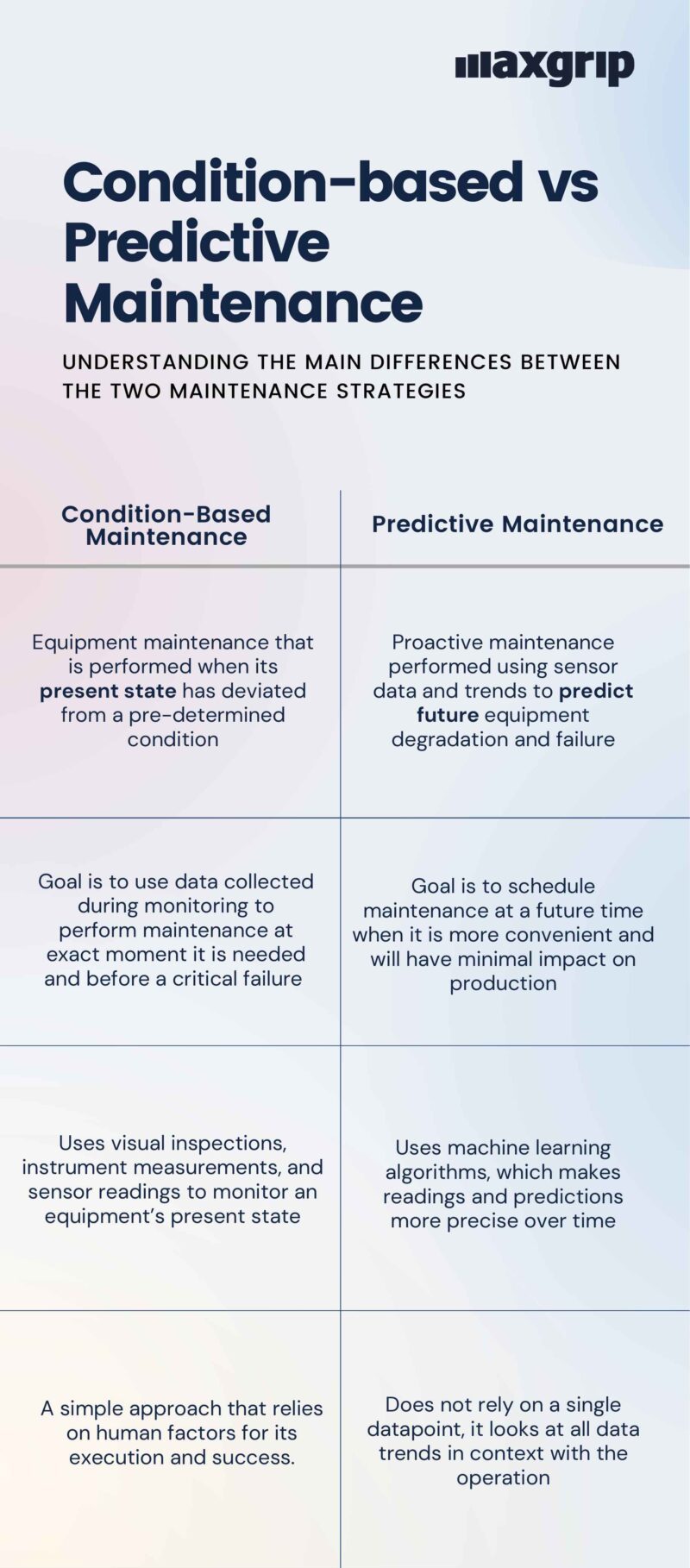

Although condition-based and predictive maintenance have some overlap, there are distinct differences between the goals of each strategy.

| Condition-Based Maintenance | Predictive Maintenance |

|---|---|

| Equipment maintenance that is performed when its present state has deviated from a pre-determined condition. | Proactive maintenance performed using sensor data and trends to predict future equipment failure. |

| Goal is to use data collected during monitoring to perform maintenance at the exact moment it is needed and before a critical failure. | Goal is to schedule maintenance at a future time when it is more convenient and will have minimal impact on production. |

| Uses visual inspections, instrument measurements, and sensor readings to monitor an equipment’s present state. | Uses machine learning algorithms, which makes readings and predictions more precise over time. |

| A simple approach that relies on human factors for its execution and success. | Does not rely on a single datapoint, it looks at all data trends in context with the operation. |

Get inspired

We share our view on 25 years of maintenance and asset performance management.

Unlock the full potential of your EAM system by transitioning from implementation to deployment, fostering operational excellence and strategic success.

Asset health is crucial for water authorities to continually meet their goals. In this article, we offer five tips to boost the health of your assets.