AVR Duiven is a waste-to-energy plant in the Netherlands. They incinerate waste with which the facility produces raw materials and generates renewable energy. The energy is used by households and businesses in the area. At this location of AVR the company also has a CO2 capture installation which provides 60.000 tons of CO2 to surrounding horticulture businesses. With their waste-to-energy plants, AVR strongly contributes to a circular economy and sustainability. In order to keep improving their efficacy and efficiency, they asked MaxGrip to help with improving their maintenance management and with getting the most out of the Enterprise Asset Management (EAM) system.

Challenges: Getting The Most Out Of The EAM System

The maintenance team of AVR Duiven had already been working with their IFS

Ultimo EAM system for a while. The maintenance manager is satisfied with this

asset management system and felt that they could make better use of it to get better results. The focus on improvement would have to benefit important KPIs such as the uptime, maximizing availability of installations and lengthening intervals between planned shutdowns. Moreover, the maintenance manager wanted to take the opportunity to improve budget forecasting by being able to substantiate costs.

Approach: Consistency and Transparency

Our consultant has taken a number of actions and steps to improve the

maintenance management and use of the IFS Ultimo EAM system of AVR Duiven.

- Finetuning maintenance strategy

Ensuring that the maintenance department focuses on the right things and doing those well. The improved Preventive Maintenance (PM) strategy meant that PM plans were improved and more PM plans were added which made planning more accurate. Maintenance execution also became more flexible due to better and more insights into required work. - Improving use of the EAM system

The PM setup in the IFS Ultimo EAM was improved, the processes were finetuned and the system was cleaned up. Our consultant concentrated on cleansing data and consistency; all of the needed information for PM models can be found in the EAM system such as throughput time, preferred contractors, materials, activities, PID etc. The improved processes and work instructions ensured standardization as

per the agreed work scope, terms, etc. The execution in the right way is also now tracked and reported. This ensured that work now less depends on one employee or contractor. - Way of working

It’s not only the data, system and processes that needs to be in order to get the most out of the assets. Our consultant also worked with the team to align the roles and responsibilities and the way of working. This ensured that the maintenance team and also contractors worked in the right way as was set out in the system and matching processes (through for example more standardization). This way of working created transparency for all, resulting in compliancy to governmental

guidelines and now being able to easily prove compliancy as everything that is done to comply to rules and regulations is reported and tracked in IFS Ultimo. - Budgeting and reporting

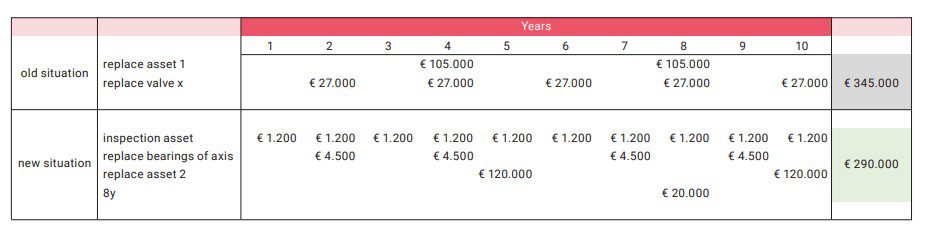

The PM models and strategy as available in IFS Ultimo are the baseline for the multi-year budget. This is now substantiated based on more planned preventive maintenance work. It enables the maintenance manager to budget for following years in a more effective manner, which makes requesting budget with senior management easier. It has also become easier to remove peaks by spreading out work and evening out spend throughout a time period.

Example for one asset: cost reduction by being able to plan better

“I am sure that with MaxGrip we have improved and progressed further than we would have been able to do without them. The MaxGrip consultant offers a fresh and holistic perspective. Not only that, but they get things done: from asking critical questions and formulating what needs to be achieved to collaborating with the team and contractors to realize goals.”

Remco Rutgers, Manager Maintenance and Engineering at AVR Duiven

The Results: More Effective Way of Working

The AVR Duiven maintenance team together with the MaxGrip consultant were able to really improve the use of the IFS Ultimo EAM system and getting the most out of it for the long haul.

- The maintenance team has become more efficient and effective;

- Transparency has increased which helps in proving compliancy and being less dependent on contractors;

- Better budgeting and reporting giving the maintenance manager more confidence and visibility with senior management due to long-term budgeting with more predictability.

Get inspired

Media interview with client TenneT about the harmonization of the (onshore and offshore) asset management.

Download our best practices checklist to make sure you’re implementing and optimizing your EAM for long term success.

MaxGrip is honored as the 2024 innovator in asset management by Verdantix, leading with cutting-edge technologies and practices. Join our webinar on May 22nd to discover more.